测量解决方案

阳极涂布

Tandem coating lines

获得产品的基线实验室测量报告

了解更多

我们的技术

联系我们的销售团队

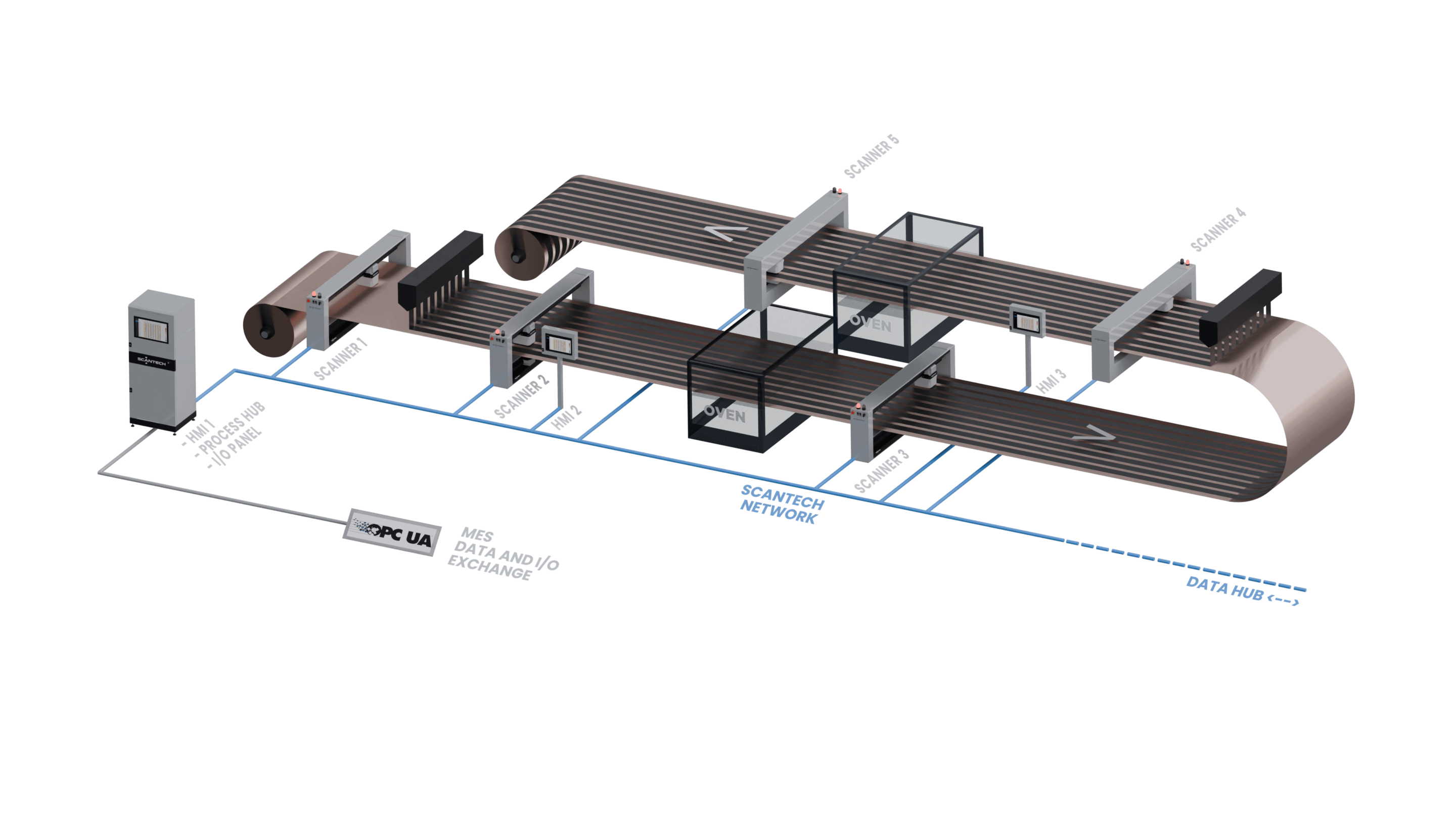

MEASUREMENT SYSTEM

5 SCANNERS USING

OUR ADVANCED SAMESPOT TECHNOLOGY

- Scanner 1 for the foil substrate

- Scanner 2 and 4 for each wet coating section

- Scanner 3 and 5 for each dry coating section

3 VISUAL INSPECTION STATIONS

- Surface inspection systems 1 and 2 for each wet coating section

- Surface inspection system 3 before the winder

人机界面

3 SUPERVISION STATIONS WITH THE FLEXSCAN INTERFACE

- 2 HMIs dedicated to the coating stations

- 1 full-line HMI inside the control room

- OPC-UA connection with the SCANTECH network

特点

RECOMMENDED SCANNERS

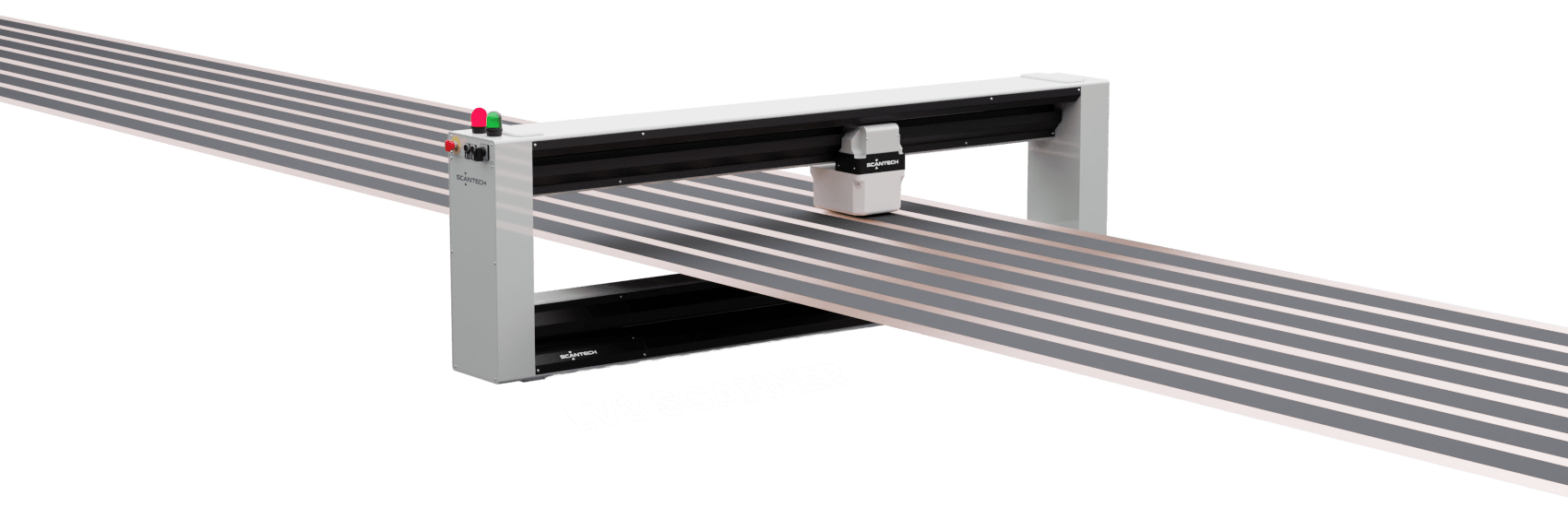

SCANNERS: 1, 2 & 4

- Type: O-Frame

- Up to 1500mm for anodes and cathodes

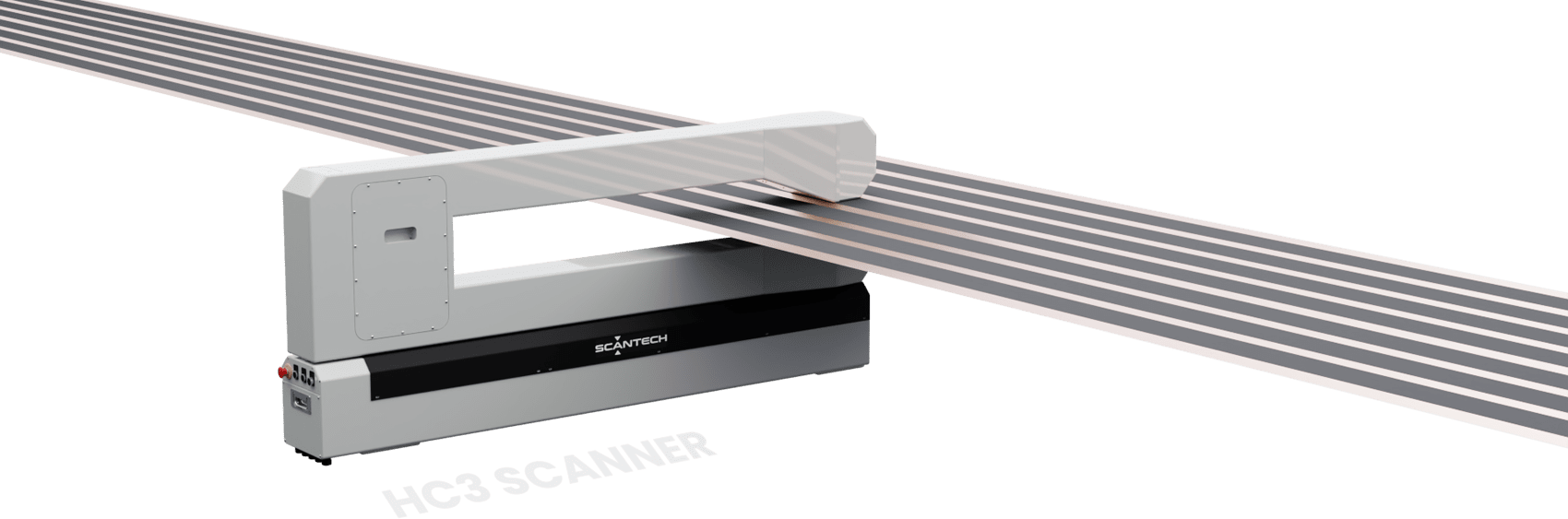

SCANNERS: 3 & 5

- Type : C-Frame if thickness is required

O-Frame if thickness is not required

测量

THICKNESS MEASUREMENT

- Technology: X-RAY transmission sensor

- Product range: 1 to 100μm

- Accuracy: Better than 0.1%

WET OR DRY COATING BASIS WEIGHT MEASUREMENT

- Technology: autocalibrated transmission sensor

- Product range: 1 to 500g/m2

- High edge detection resolution

- Repeatability: Better than 0.1%

- Autocalibration: ± 1% of absolute value

- “Bunny ears“ profile visualization

ADDITIONAL

DRY THICKNESS MEASUREMENT

- Technology: optical sensor

- Product range: 1 to 3000μm

- Accuracy: ± 1μm

OPTIONAL

DENSITY MEASUREMENT

-

Technology: optical sensor + autocalibrated transmission sensor

目视检查

缺陷检测

- CD resolution: <100μm

- MD resolution: <100μm

- Defect classification

GEOMETRY MEASUREMENT

- Geometric figure control, including double-sided overlapping patterns and ceramic coating

- Patterns and stripes

- Accuracy: Better than 0.1μm

TRACEABILITY

- Data Matrix Code (DMC) interpretation

获得产品的基线实验室测量报告

了解更多

我们的技术

联系我们的销售团队

紧凑型设计

LV3 SCANNER

推荐扫描仪

紧凑型设计

HC3 C 型框架扫描仪

推荐扫描仪

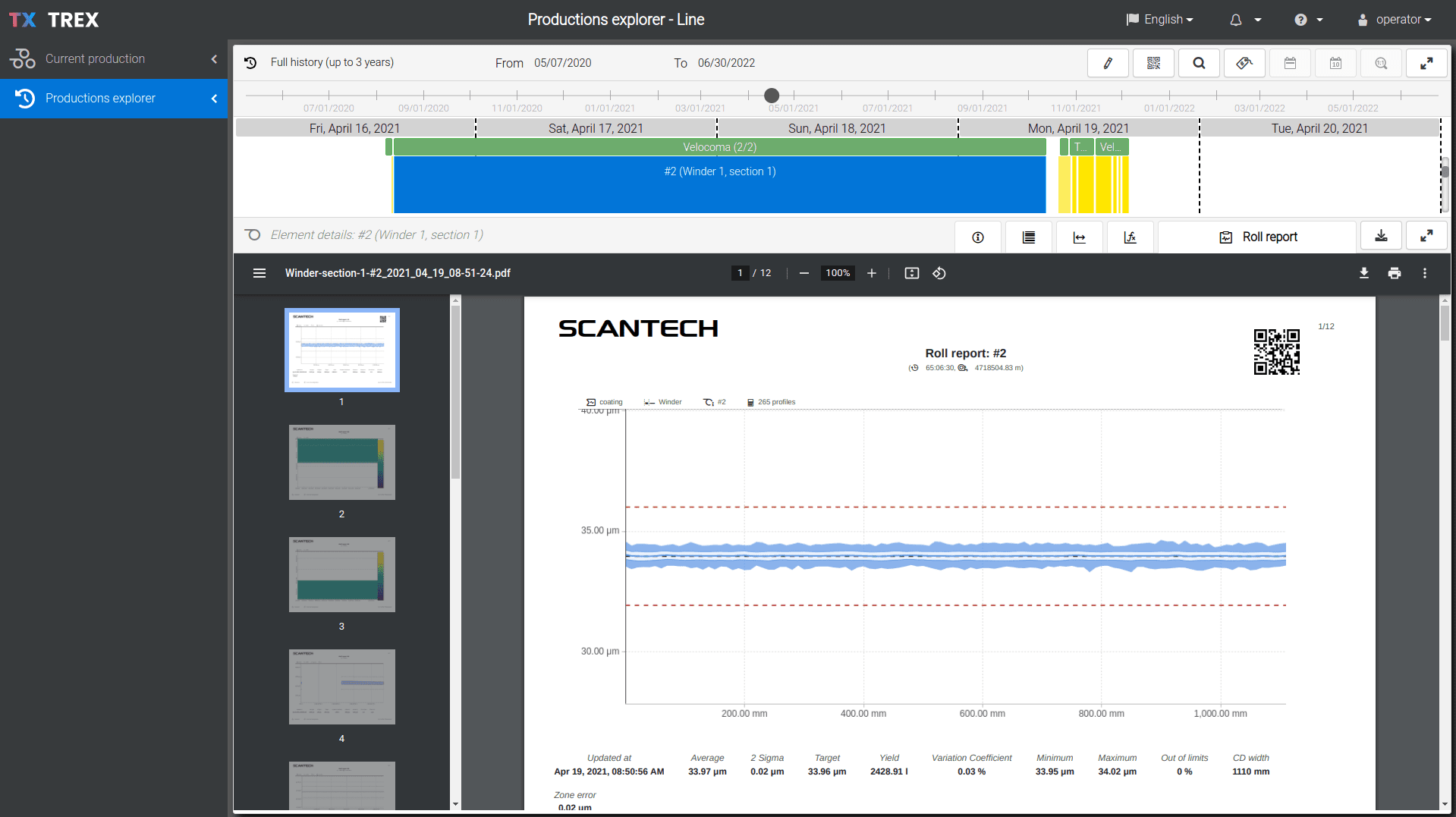

Graphical representation of both substrate and coating lanes.

Interactive profiles and trends of single and multi-strip production.

同步扫描仪

Advanced Same Spot Measurement ensures accurate net coat-weight calculations by ensuring that the substrate and coat scanners traverse precisely the same trajectory on the web, even as line speed varies.

This synchronization eliminates sensitivity to point-to-point variations and formation in the substrate material.

TREX 应用程序专门用于浏览过去和当前的生产报告。 我们独特的标签系统可对存档报告进行检索、排序、分类和整理。

收集特定客户在过去几年中的所有报告,或查找使用特定配方的产品的所有报告。

根据自己的需要定制标签,几乎可以实现无限可能!

获得产品的基线实验室测量报告

了解更多

我们的技术